CONTACT US 24/7 WHEN YOU NEED OUR SERVICES...

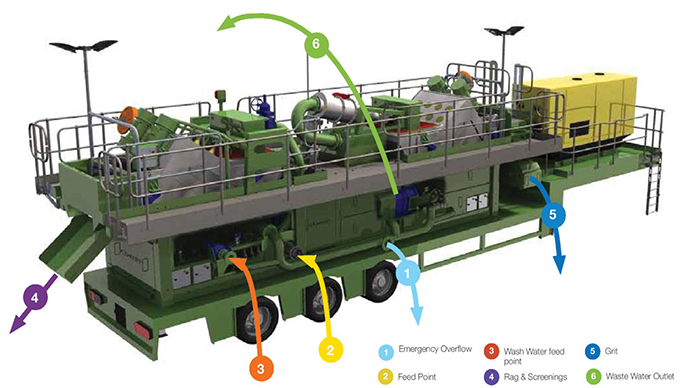

The CDEnviro D:Max is a mobile grit & screenings separation unit, mainly for use within the waste water industry and is a must for all cleaning projects within sewage treatment works when undertaking the cleaning of grit channels, PST, wet wells, storm tanks, etc.

Used in conjunction with our Disab Vacloader’s and Liquid Ring artic tanker units, the D:Max delivers thousands of pounds in savings on your waste disposal costs. Washing and separating the grit and screenings from the waste coming from your storm tank or digester would allow the grit to be recycled and used as a bulking agent in green waste composting processes, land remediation, and other recycling outlets. Whilst at present the screenings still go to landfill, the total tonnage is greatly reduced, thus saving you thousands of pounds in tax.

The D:Max is mounted on a standard step-frame trailer and has its own power unit fitted, which allows it to work remotely but it can be connected directly to a 3-phase power source if available on site. Power it up, connect a water supply from a hydrant or a wash-water supply source, and it’s good to go. Plug & Play – It’s as simple as that! As soon as you feed the waste into the D:Max, it will start saving you money and having a positive effect on the environment and your waste.

The D:Max is the way forward

Willie Lindsay, a specialist Waste Water Treatment Manager who has been responsible for Shieldhall STW and other high profile and sensitive assets over many years, said:

‘When Enviro-Clean approached me with the benefits of such technology, I did not believe it at first. How could I save money when I had to pay for yet another piece of plant?

However, when the plant started to immediately produce clean-washed grit that was fit for recycling, I was astonished. The environmental and financial savings cannot be ignored. The D:Max is the way forward, anything else is now old-fashioned and costly.’

The success of this trial has led to local Operational Managers insisting on the use of the D:Max when cleaning storm tanks, pumping stations, digesters and primary settlement tanks, thus saving money and helping the environment.

D:MAX Applications

The D:MAX is a mobile screening and classification system used to recover materials from a variety of industries, thus diverting them from landfill sites.

The D:MAX can be used for the effective screening and classification of a wide range of materials including:

- Digester Waste

- Lagoon / Pond Cleaning

- Tank Cleaning

- Wet Well Waste

- Inlet Grit Washing

- Silt Management

- Food Waste

- Mobile Dewatering

- Mobile Tanker Screening

Within all of the waste streams listed above there is a large proportion of silt, sand, grit, gravel, pebbles, stones, and other larger mineral materials.

Our extensive experience in the industrial cleaning sector and in using the D:Max ensures we are able to tackle efficiently any project involving the removal and screening of the above waste streams, thus saving you money and improving the carbon footprint of your business.

SCOTTISH WATER – SHIELDHALL STW

Scottish Water is committed to maintaining its assets and ensuring they are always at optimal operating performance to treat waste water across the country and to benefit the environment.

Part of this strategy is to regularly clean the 6 Inlet Channels at Shieldhall STW in Glasgow. These works are the largest in Scotland. As such, regular cleaning projects take place across all of the works’ assets to ensure compliance and reliability.

By using the D:Max, Scottish Water saved 56% per lane over the traditional skip and landfill process — £18,350 as opposed to approximately £31,950 per lane, giving total project savings of £81,600. These savings can now be invested into other areas of the business to ensure Scottish Water continues to meet its customer service levels and has a positive effect on the local and national environment.

STORM TANK CLEANING

Usually, storm tanks are cleaned out by way of vacuum tankers sucking out sludge/rag/grit and transporting the waste to the nearest largest sewage treatment plant that could handle a large amount of incoming waste.

This only moves the waste from one asset to another; the problem is not being dealt with as the waste remains in the treatment process. Invariably, this amount of waste would end up overloading screens and the grit removal process, causing them to fail and in some cases to break drive chains and other mechanical parts.

By using the D:Max you can remove the waste from the treatment process and protect your plant and machinery from shock loads, whilst helping the environment and minimising your spend.

Oversize grit/gravel can be recovered for use as recycled aggregates and recovered organics/rag can be used in composting or alternatively go to landfill at reduced volumes. Without the D:Max, these materials would all go to landfill, incur significant disposal costs and adversely impact the local environment.

How does the D:Max work?

- The D:Max will be operational within 90 minutes of arrival on your site.

- When the trailer level and the water feed and discharge hoses are connected, you can decant your waste into the inlet pipe. The D:Max will add water, shake it, screen it, separate it and return the wash liquor to the treatment process whilst filling your skips and saving you money. That’s it!

- The process is very easy and straightforward, with no fuss.

- To further increase the environmental benefits and lessen your cost, the D:Max can also use final effluent to wash the waste during the separation process.

Why use the D:Max

- Reduces transport costs

- Ensures compliance to Landfill Directive

- Separates grit and screenings into 2 skips for easy storage

- Recycles waste grit for composting and land remediation use

- Reduces waste to landfill by 70%

- Minimises your Landfill Tax

Son of D:Max! The MSU:10 single screen system is ideal for deragging sludge from private & public septic tanks and wastewater from public and sporting events, prior to final treatment. It is deployed to site via a standard 8yd skip lorry and will be ready to start work in minutes.

“The environmental benefits of using the D:Max, combined with the considerable cost savings on waste disposal and landfill tax, make the use of this technology a must for all waste water tank & digester cleaning projects. The savings have amounted to thousands of pounds…”

Waste Water Team Leader, Leading UK water company